Need further assistance?If you are looking for some additional information or support, feel free to get in touch with our packaging experts & sales team.

RB-06

Drawer Rigid Boxes

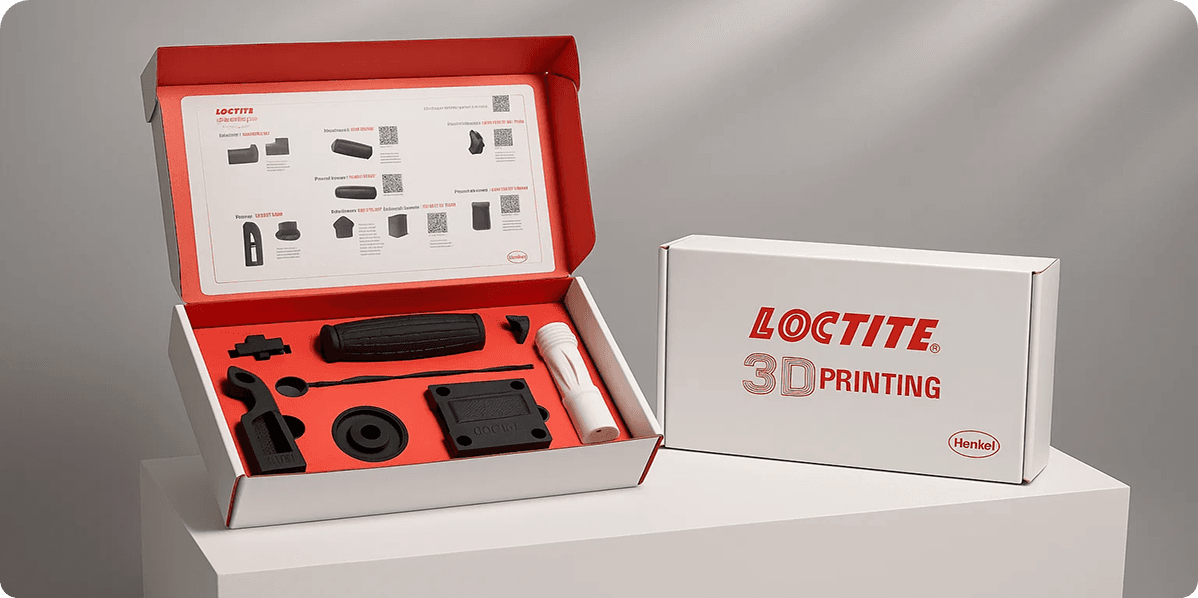

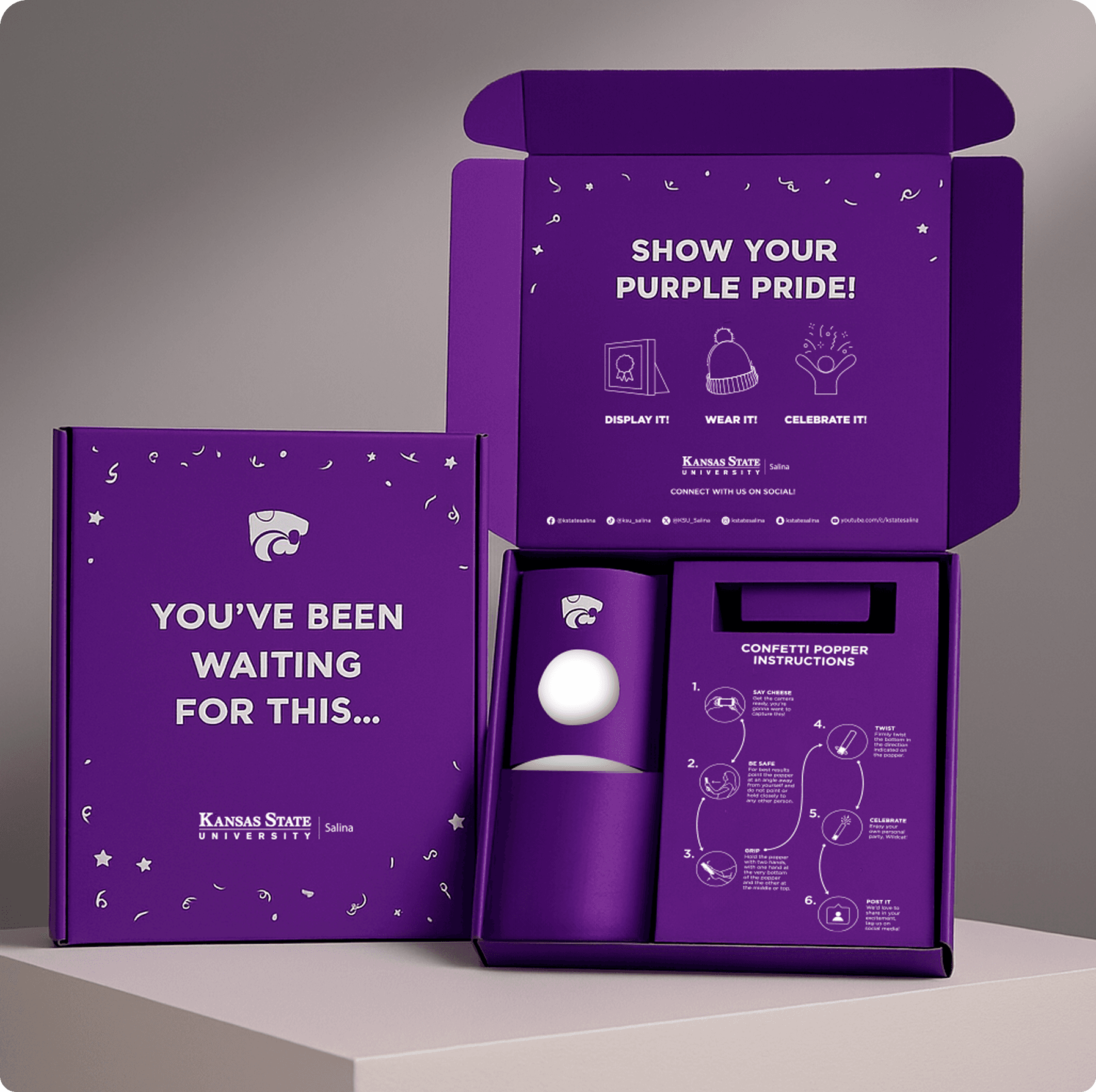

Drawer or slide rigid boxes feature a sliding tray and outer sleeve construction, offering both elegance and practicality. Ideal for premium products needing easy access with secure enclosure.A Personalized Packaging Experience Tailored to Your Needs

Product OverviewFeatures a sliding tray and outer sleeve construction | Board Construction1.5–3 mm greyboard for both the outer sleeve and inner drawer. | Tolerance0.5–1.0 mm for controlled motion and durability. |

Outer WrappingIndividually wrapped sleeve and tray with various paper options. | WhiteWhite or premium white coated and uncoated paper. | Kraft PaperEco-friendly kraft paper for sustainable choices. |

Color & Print OptionsEmbossing, foil stamping, or spot UV can highlight brand marks | CMYK & PantoneCMYK and Pantone printing options available for inside and outside | PrintingOffset printing for ideal print result and cost optimization. |

Understanding the Construction of Custom Drawer Rigid Boxes

Precision in sleeve-to-tray tolerance determines how smoothly the drawer slides. Even slight misalignment affects motion and fit. Plan ribbon pull position, insert thickness, and paper grain direction early for a clean finish.

StructureTwo-Part System for Controlled MotionComprises a rigid outer sleeve and an inner tray. The sleeve acts as a shell while the tray holds the product and slides seamlessly inside.

Construction TechniquesReinforced Drawer Walls & CornersBoth parts of custom drawer boxes are wrapped individually. Tray corners are mitred and glued, sleeve joints pressed flat for smooth edges.

Details & Add OnsFunctional and Aesthetic EnhancementsAdd ribbon pulls, magnetic edges, or foil accents. Optional window cutouts, printed liners, or inserts can customize the drawer rigid boxes reveal experience.

Making Your Brand Unforgettable

Need Help Designing Your Hinged Lid Box?

We provide free in-house design support

Frequently Asked Questions

Get answers to common questions about custom rigid boxes, or visit our Help Centre for further information.How do collapsible rigid boxes fold flat?

They use taped or fabric hinges that allow side panels to collapse inward, reducing volume for shipping.

Do they require manual assembly?

Yes. Boxes ship flat and are assembled in seconds by folding side walls into place.

What’s the lead time for production?

Standard turnaround is 10–14 business days after dieline approval.

Are they as strong as fixed rigid boxes?

When assembled, the interlocked corners and thick board restore full rigidity comparable to setup boxes.