Need further assistance?If you are looking for some additional information or support, feel free to get in touch with our packaging experts & sales team.

RB-02

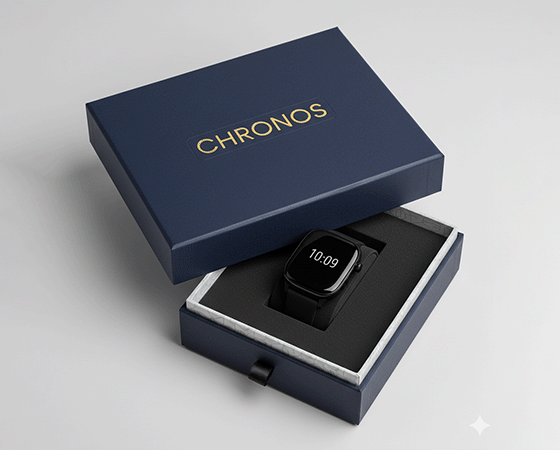

Shoulder & Neck Rigid Box

Custom Shoulder and neck rigid boxes combine structure and sophistication through their three-piece design, base, neck, and lid.A Personalized Packaging Experience Tailored to Your Needs

Product OverviewGreyboard or Chipboard core for strength | Board ConstructionMost commonly used with a flute thickness of 1.2-2mm. | Structural StrengthThe shoulder and neck layers add extra rigidity and prevent lid warping |

Outer WrappingBase materials for printing that are glued to the corrugated boards. | WhiteWhite (uncoacted/matte) & Premium white (Glossy/coated) | KraftSustainable & eco-friendly naturally brown Kraft. |

Color OptionsHighest quality inks with vibrant and lasting printing outputs. | CMYKIdeal for printing a range of colors in an affordable cost. | PantoneIdeal for printing a range of colors in an affordable cost. |

What to Know Before Designing Custom Shoulder and Neck Rigid Boxes

The alignment between the neck and outer lid must be flawless, as even minor discrepancies can affect both appearance and functionality. From selecting the right board thickness to ensuring a smooth lid glide, every structural and finish choice determines how premium the final box feels.

StructureThree-Piece Design for Extra StrengthThese boxes are built with a base, neck, and lid, where the neck is partially or fully exposed between the two parts. This adds rigidity, increases stacking strength, and creates a smooth, elevated opening motion.

Construction TechniquesStructure That Supports LuxuryThese boxes rely on sturdy greyboard, usually between 1.5mm to 3mm thick to maintain shape and support the layered structure. Thicker boards ensure a firm base for the neck but must be chosen carefully to avoid adding unnecessary bulk or weight.

Details & Add OnsCustom Heights, Fits, and FinishesPremium paper wraps (from 120–150gsm) are used to cover each component; base, neck, and lid—individually before assembly. Common finishes include soft-touch lamination, anti-scratch matte, or specialty textures.

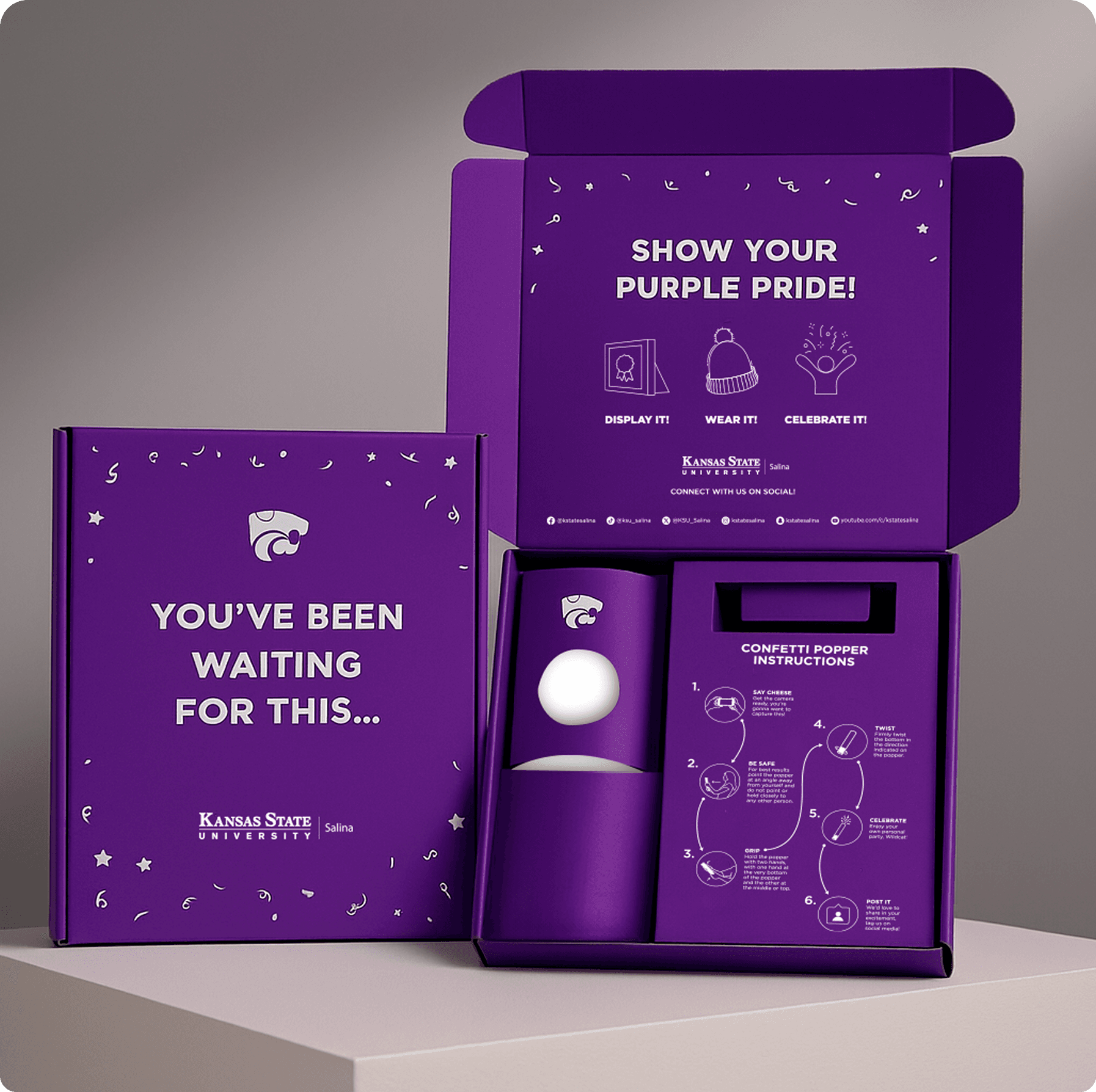

Making Your Brand Unforgettable

Need Help Designing Your Rigid Box?

We provide free in-house design support

Frequently Asked Questions

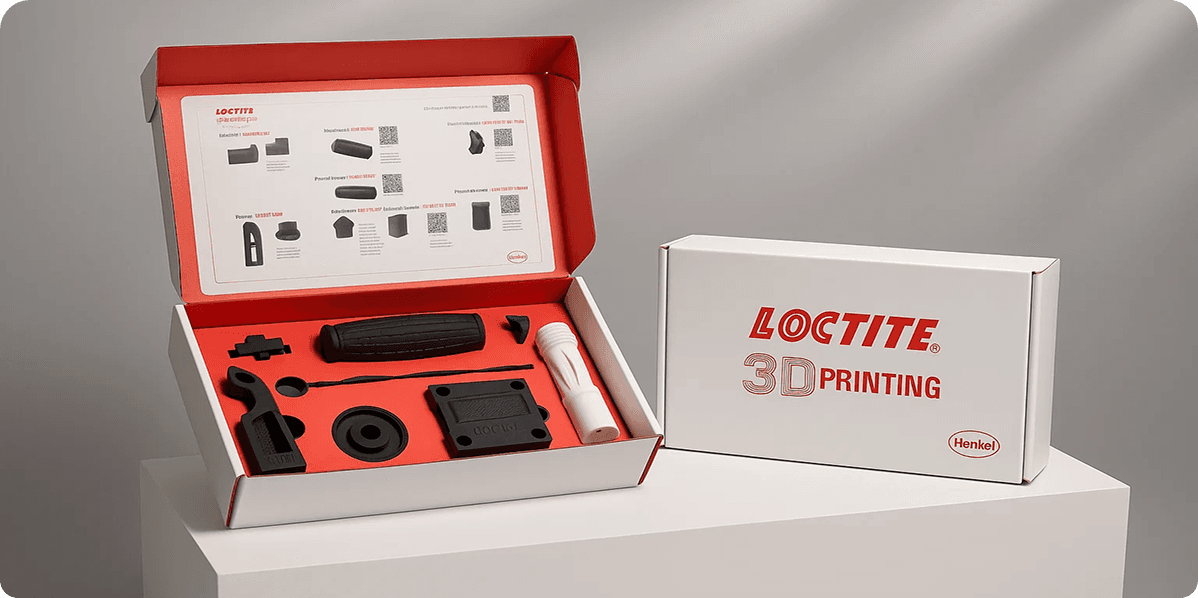

Get answers to common questions about custom rigid boxes, or visit our Help Centre for further information.Can inserts be made for sets or multi-product packaging?

Yes. Inserts can be designed with multiple cavities or tiers to hold different products in one box — perfect for gift sets, PR kits, and subscription boxes.

What are inserts used for in rigid boxes?

Inserts help hold products securely in place, protect them from impact, and improve presentation. They also make unboxing more organized and premium by framing each item neatly.

How do I choose the right insert for my product?

Consider your product’s fragility, weight, and packaging goal. For example, EVA is great for high-end items, EPE for reusable packaging. Get in touch with us for more info.

Can inserts be customized with color or branding?

Absolutely. Foam inserts can be dyed or covered with printed wraps, and paper-based inserts can be laminated or embossed to match your box design and brand colors.

Are all Inserts Eco-Friendly?

Not all — but cardboard and molded pulp inserts are fully recyclable and biodegradable.