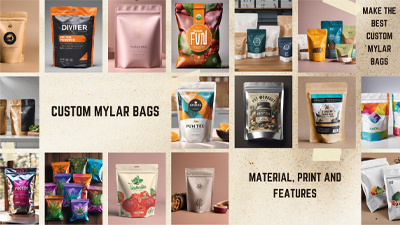

Designing the Best Custom Mylar Bag: Advice on Material, Print and Features

Custom Mylar Bags have become a staple in modern packaging due to their strength, versatility, and unparalleled protection against all contaminants. As the name suggests, Mylar Bags are commonly designed for food and pharmaceutical products. However, their use spans various other categories of products, such as electronics and cosmetic products, which emphasizes how versatile they are when it comes to branding and packaging.

In this guide, we will examine how you can customize the best-quality Mylar bags for your product, examining materials, printing techniques, and key packaging features that ensure they meet your product’s functional requirements.

The Purpose of Mylar Bags

Before we delve into how to make custom Mylar Bags great, let’s first understand why brands opt for this type of packaging. Compared to corrugated cartons and rigid boxes, Mylar Bags are not only different visually but also have a chemical composition that makes them incomparable to any other form of packaging.

Made from polyethylene terephthalate (PET), Mylar Bags are popular because of their exceptional barrier properties. They are designed to keep edible dry and wet items protected from external contaminants such as air, light, moisture, and bacteria. They are used for, but not limited to:

- Food Packaging

- Medicine and Oils

- Cosmetics and

- Electronics

The Choice & Considerations for Material

This part of Custom Mylar Bag packaging confuses many of our customers. Because isnt is the same material always? Well, there are many “layers” to it.

Mylar bags are composed of several layers, each having a specific purpose and influencing the durability and functionality of the bag.

- Outer Layer (PET): As discussed above, the outer layer of a Mylar Bag consists of PET, which is resistant to moisture and tearing. This layer also provides a smooth surface for different types of printing and finishing.

- Middle Layer (Foil): The aluminum foil prevents air, light, and moisture from entering.

- Inner Layer ( Polypropylene): This layer provides the ultimate safety to the product, keeping it safe from contamination and enabling heat sealing.

When finalizing the materials, here is what you need to consider:

- Product Sensitivity: What level of protection does your product need? If it is an edible and perishable item, opt for a thicker middle layer of foil.

- Bag Thickness: Standard thickness ranges from 2.5 mil (lightweight) to 7 mil (heavy-duty). Choose based on the weight and type of product.

- Sustainability: Eco-friendly options include recyclable or biodegradable films for brands prioritizing sustainability.

By carefully selecting materials, you can ensure that your Mylar bags meet the specific requirements of your product while maintaining cost efficiency.

Customizing Design for Mylar Bags

Now that we have sorted the technicalities, it is time to explore the fun part: Design & Aesthetics. Mylar bags offer a great deal of flexibility when it comes to customization. Let’s start with the printing options we have:

- Direct to Mylar

- Sticker on Mylar

Direct to Mylar:

As the name suggests, this type of printing involves the direct application of the visual or design on the surface of the bag. A specialized machine containing durable inks is used for direct printing on mylar bags, resulting in a finish that is not only long-lasting but ideal for multi-colored and detailed designs.

However, there is a catch- Direct printing has a high setup cost as it requires specialized equipment and also takes longer than the second option, stickers.

Sticker on Mylar:

Alot of brands disagree with this approach merely because the sound of stickers sounds unprofessional to them. However, the Mailer Box has had the opportunity to produce a wide range of impeccably designed sticker on Mylars. These are not only a more cost-effective solution, but ideal for small volumes and simpler designs. And at the same time, it offers good options for customizations and flexibility in placing the designs.

However, if you are looking for multi-colored intricate designs, then stickers may not be the right choice for you.

Which way to go?

Customization in Mylar Bags is quite straight forward. You either go for the budget-friendly option that supports your minimal designs, or you go all out with intricate designs and durable printing. So eventually what works for you best depends on what your budget is and how detailed your custom mylar bag designs are.

Understanding the dimensions and sizes

Mylar Bags can be customized into different shapes and sizes. And in addition to that there are standard sizes that can work for items that go by weight or volume rather than sizes. For example, dry edible powders can be easily packed in standard sizes based on the weight of product that goes inside.

1:Small Size:

This is the ideal size for giveaways and samples, which come in 4 in x 6 in or 3.5 in x 5 in.

2:Medium Size

If you are looking to pack moderate-sized products like coffee, dry fruits, tea, or jewelry, the 6 in x 9 in is a good size to explore.

3:Large Size

The large size is ideal for more extensive and bulkier products. It is available in sizes of 10in x 14in or 8 in x 10.

4:Extra-large

The extra large size comes in 14 in x 20 in or 12 in x 16 in. It is mainly used for oversized products with larger weight/volume.

Understanding the size requirements for Mylar Bags:

Before you make a decision about the sizes, there are a few things to keep in mind:

Volume of the Product:

If it’s a non-edible item, measure its exact dimensions and take into account the total volume. This practice is essential to ensure that your product snuggles comfortably into the bag without overfilling or leaving extra.

- Custom Inserts:

If you plan to insert customized protective materials such as trays, cards, or bubble wraps, consider the additional space before opting for standard sizes.

- Opening & Closing

You must ensure that your pouches are easy to open and close and that there is minimal risk of spillage in both cases.

- Customization & Aesthetics

Take into consideration how creative you want to be with your final outlook of the Mylar Bag. Ensure that your designs, product dimensions, and type match the size and aesthetics. You always have the choice to opt for customized sizes for added flexibility and protection. There are a variety of shapes you can customize your sizes into:

- Flat pouches: These are for products with minimal depth, like seeds, papers, etc.

- Zip lock bags: For optimal protection and airtight seal to keep the product safe from external elements

- Stand-up pouches: For retail display and dry edible food items such as coffee or tea.

Conclusion:

Custom Mylar bags are one of the finest addition in custom packaging. They are flexible, budget-friendly and lightweight. With some simple customizations you can create a fascinating retail display for your products using Mylar Bags.

Ayesha Khubaib

Ayesha has a diverse experience in areas of marketing and management. Over the years, Ayesha has been involved in the packaging sector in various capacities and now aims to share packaging market insights with her readers

Ready to think outside the box? Let’s get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.