Offset printing is the most well-known technique for mechanical printing. More or less, the page text and pictures are places in a couple of essential colors (generally Cyan, Magenta, Yellow, and black) and each shading picture is ‘engraving’ on a slender steel plate.

Sports & fitness boxes are more than just containers for your game discs. They’re the first impression that people will have of your game and company. A stylish, well-designed game box can make people want to buy your games, while an amateur-made one may deter them altogether. It’s important to take the time to plan how you want your box to look before designing it. There are several factors you’ll need to consider in order to make sure that your game box is both beautiful and practical. Here, are some tips on how to design custom-made sports box packaging that will attract gamers everywhere!

The most well-known completion is a covering. This is a layer of varnish that covers all in all print, fixing and shielding the ink and paper from rubbing and spreading. Coatings can be applying at the print machine stage, or be shower on the complete prints.

The coating can be matte, semi-gleam or shiny, and will influence the presence of your print definitely; Glossy coatings make the print look more differentiated, with more profound darks and shadings; matte coatings will marginally curb the tones and darks.

A few layers of coating can be applying, and covering can be printer similarly to printing ink. This considers extravagant impacts, for example, a general matte covering for certain pieces of the print canvassed in a glossy coating.

UV covering is a special sort of packaging made of a polymer that solidifies when presented to UV light (this is called relieving).

At the end of the day, they’re what makes your games stand out on store shelves against all the other games. They’re what make your game feel special and not just another generic product. Without them, you would probably pass right over your favorite game without even knowing it was there.

Custom-made sports box packaging is where it’s at these days, and if you want your games to be seen in stores, this article will give you everything you need to know about how to make them stand out!

Whether you’re a game publisher looking for a new look, or just an individual with a great idea for custom packaging, we’ve got what you need. We specialize in original and exclusive video game box design and printing. We work closely with your marketing and branding team to create the perfect look for any occasion. From the first-time release of your favorite new game to the launch of your own personal gaming brand, we can help you get the right package so that your product stands out from the rest.

Perforated packaging for toys can be defined as cardboard material that is packed with small holes to allow its use (generally, kids) to breathe easier during the use. This concept of improvement was developed keeping in mind the dangers posed by suffocation and choking hazards when children were playing with objects.

Perforated packaging for toys was created with the motive to ensure the safety of children. Nowadays, many companies produce such toy boxes and other perforated accessories as well, so as to make them available in every household easily.

These segments are made of printed paper mounted on a cardboard core, which is then die-cut into shape as indicated by your requirements. This likewise puts table game creation out of the alliance of most printers. Printers have practical experience in imprinting on paper, typically utilizing balance presses as depicted previously.

The Mailer Box has practical experience in box packaging or publicizing/retail location shows and has the necessary devices and skills for that sort of work as well, however, most business printers don’t.

Box manufacturers offer custom cardboard boxes that are of the highest caliber around and have distinctive competing alternatives to suit your necessities. Browse numerous choices for your custom unbending boxes, for example, overlay, box size, and materials. Each side of the custom clear game boxes is completely adaptable with your own designs.

An online custom printing organization having some expertise in games printing and games producing. Their exclusive expectation savvy costs, a total print on the interest arrangement that is respectable in the board gaming industry.

Benefits of Using Custom made Sports Boxes:

Sports & fitness boxes are normally white and have simple cardboard boxes on the side, with the front featuring the company logo and the inside containing the game’s instructions and usually a secret code to open. In some cases, the box may also include a game controller. These are the basic box styles available today. They can be customized by adding a wide variety of accessories including character posters, game sleeves, and more. The advantage of these specialized box styles is that they are unique and don’t just copy another style that is used by many other companies, allowing consumers to show their own personalities.

Sports & fitness packaging comes in several forms. For the most part, this packaging will include the front cover, instructions, front flap, inside flap, and the back cover (if the box includes one). If the box has additional features, such as game walkthroughs or cheat codes, the packaging will also contain additional information. Generally, all of the information you’ll need is included in the packaging.

The Mailer Box is specializing in custom packaging. If you’re looking for a custom sports & fitness box, for example, you’ll need to speak to the custom box manufacturer directly. We allow our customers to choose their own box art and have them designed and printed by our team of Experts. You can use your own photos or artwork, or the company’s design team can help you with this process.

| Dimensions | Custom Shape & Dimensions (length x width x height ) |

| Printing | CMYK Offset Printing, Spot Color, PMS, Plain Screen Print, Digital Print |

| Paper Stock | Box Board, Kraft, Art Paper, Matt Paper, Bleach Card, Uncoated |

| Extra finish | Matt, Gloss, Foiled, Spot UV, Textured |

| MOQ | 100pcs |

| Included | Bundling, Die Cut, Pasting & Gluing, Creasing, Perforation |

| Additional | Window Patching, Emboss, Foil. Debossed, UV |

| Design Proof | Die Line, 3D Digital Mockup with All Possible angles, Physical Sample On request |

| Turn Around | Production time: Corrugated 7-10 working days Product Boxes 4-6 working days |

| Shipping | Shipped Flat for all boxes except rigid boxes Shipping VIA FedEx, Ups, DHL 4-6 working days for shipping |

If your graphic files do not meet our specifications, The Mailer Box will not be charged for any resulting

typographical errors. Read our artwork preparation to prepare your files for submission, or contact us for help from

a packaging specialist!

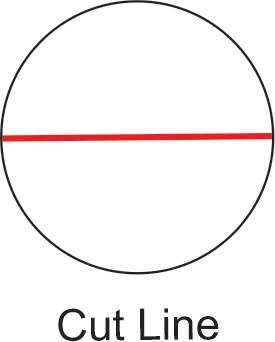

Displays the section in its final size and where the box should be folded. Important graphics

and text should be placed at least 0.125 inches from the cut line.

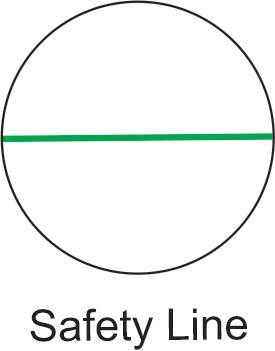

Indicates where the drain section is located. All graphics that run-up to the cut line should be

extended to the cut line for a transparent print.

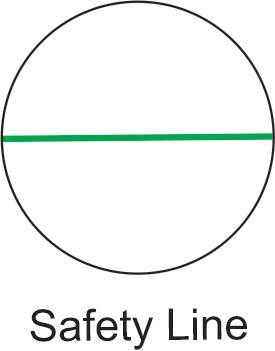

Specifies where to safely place illustrations and text. As an industry-standard, all graphics

should be placed at least 0.125 inches from the cut line unless your design is intended.

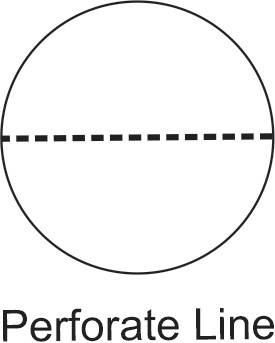

The perforaation line refers to paper punched with very small holes to make it easier to tear and

fold the paper.

| Choose your Custom Product | Choose your desired product from our website. If you can’t find what you are looking for fill in the message section and add your custom requirement. Our representative will guide you throughout the process |

| Fill the form | Once you have found your product mention that in the form with the dimensions with the unit, Order quantity, Material requirement, extra finishes if any, and if there is any custom requirement. Our sales team will get back to you with the quote within 12 hours. If there is any urgency you can call us directly at +1(801)-783-4566. |

| Place the Order | Your order will proceed on payment confirmation. |

| Artwork preparation | f you have your artwork ready our design team will send you the final die lines and digital mockups for confirmation. If you don’t have a ready design your contact our team and ask for design support without any additional charge |

| Production & Shipping | Once the design is approved we take 4-6 working days for cardboard product boxes, 7-10 working days for corrugated boxes, 10-14 days for rigid boxes. Shipping generally takes 4-6 working days. |

At “themailerbox” we have the best team, with state of the art manufacturing unit to provide you with high end fully customized packaging.

If you have any question, please contact us at info@themailerbox.com

10972 glenda ln south jordan ut 84095

No products in the cart.