How much does the quality of Paper matter in packaging?

Custom packaging plays a significant role in building the perception and need of your product in the market. While it is essential to protect the items it holds, its role in branding your product is invaluable. While packaging has several components that combined make a great piece of art, paper is one of the key elements that make or break the quality of your custom packaging.

High-quality materials used to design your mailer and custom box have a long-lasting effect on the marketing efforts and perception of your product in the market. It allows your consumer to perceive your product as luxurious, well-crafted, high-quality, and durable. Whereas quality packaging has detrimental effects on both your product’s perception and its marketing success.

In this blog, we will discuss the different varieties of papers used in packaging and how the quality of paper plays a crucial role in printing and eventually custom boxes.

Choosing the Paper

In packaging, there are different types of papers used based on need, aesthetics, and budget. However, some of the essentials of selecting the right paper for your custom packaging include:

- Basis Weight

This is the per unit area of the paper. It is an integral part of testing the paper’s durability and resilience. More basic weight indicates that the paper is strong and handle the stress of transportation, weight, and changes in weather. However, basis weight also defines the cost of the paper. Naturally, the higher the quality of the paper the higher the cost of it.

- Coating

The coating is another important factor that not only the strength but also the visual performance and printing quality of your packaging. For instance, many people choose clay-coated papers to enhance the appearance of their boxes and add an extra layer or protection to their packaging. Clay-coated papers prevent liquid and moisture from easily damaging the paper, acting as a barrier between the box and the product. Similarly, matte lamination adds a sophisticated and luxurious appeal to your packaging. It has a velvet-like feel that gives a very classic and subtle look to your printing.

- Paper grades

There are a variety of paper grades that are selected based on their cost, strength, requirement of the packaging, and application. It is essential to learn about the benefits and drawbacks of each to make an informed decision about your packaging material.

Two of the most common types of paper grades are:

- Natural Kraft

Also known as SUS, kraft paper is a sustainable and eco-friendly material that has a very raw feel to it. It is made from recyclable materials and is ideal for companies selling holistic and organic products. Many brands are shifting towards sustainable packaging, and natural brown kraft is a popular paper choice for them. Composed of unbleached pulp of wood, the raw uncoated appeal is the standout feature of this paper.

However, it has some limitations to it, especially from an aesthetic perspective. Because it is not coated, it may not be able to deliver you vibrant and rich colors in print as the paper absorbs most of the ink.

- Box Board

Folding box board is a common type of paper used in packaging. It is composed of mechanical materials and a combination of different types of chemicals to create a multi-layer sheet that is resilient and exceptional in strength. Box board sheets deliver the best quality prints compared to other papers. They are popularly used in cosmetic and luxury product packaging.

- Bleached Sulfate Board

Another special paper grade is made from chemically processed pulp that is later bleached before being formed into shapes. The sulfate board has a clear white surface on both sides of the box and is ideal for high-resolution prints. If you are looking to get different types of finishings on your box, this may be your go-to option.

Testing the Paper

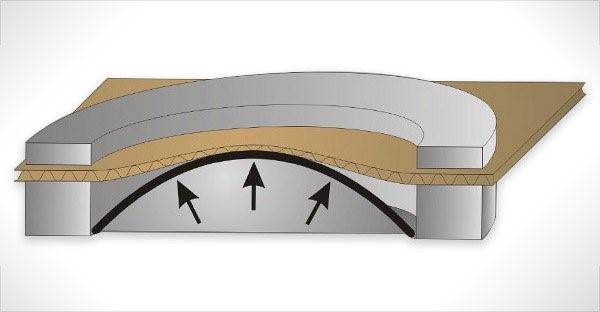

Burst Strength

What is the most significant function of a box? To protect the product from damage. Testing the burst strength of the paper is essential when selecting a paper for custom packaging. If you are planning on packing bulky and high-volume products, test them for tears and temperature resistance. High-burst strength is critical and highly recommended for heavy products that must be transported over long distances.

Sustainability

Another important consideration is the recyclability of the paper. Many companies across the globe are shifting towards sustainable practices to minimize their carbon footprint. Recycled paper is composed of natural fibers that can be repurposed. So if that’s your goal, you may want to achieve that through paper choices such as natural kraft.