Offset vs. Digital Printing: Which Printing Technique is the One for You?

A detailed comparison between digital and offset printing to help you make an informed decision about the right printing technique for your packaging needs.

If you’re managing a brand, there is a good chance that you’ve heard of the ever-so-important 4 Ps of marketing. According to the scholars Lahtinen, Dietrich, and Rundle-Thiele (2020) the marketing mix or the 4 Ps model (Product, Price, Promotion, and Placement), is a well-researched marketing model applied and perfected over the years. Okay, but why are we discussing this marketing technicality on a customized packaging manufacturer’s website?

This is because the element of ‘packaging’ is an important component of ‘product’ itself. Product packaging is an extension of the product which means that the effort you’re putting into creating the design and structure of your custom packaging adds directly to the value of your product and from there to the value of your brand.

While several elements contribute to the functionality and structure of your customized packaging, the print on the box conveys your message to the customer. Apart from adding critical visual appeal to the customized box, package printing also provides a medium for informing the customers about the brand and product(s) inside the package.

However, like everything in life, printing is not a simple process and comes with a variety of techniques, each with its pros and cons. The printing technique would have a notable effect on the print quality, the final cost of the packaging box, and the delivery times.

Your custom packaging manufacturer should be able to guide you about the values and limitations of each type of printing technique. This article intends to provide vital information about different printing techniques in packaging to help you make an informed decision:

Within the packaging industry, mainly two types of printing techniques are popular:

- Offset Printing

- Digital Printing

Other printing methods, less commonly known and used, but that are still important within the packaging industry include:

- Flexographic Printing

- Gravure Printing

- Screen Printing

This article will provide an in-depth evaluation of the offset and digital printing methods and briefly describe the remaining three.

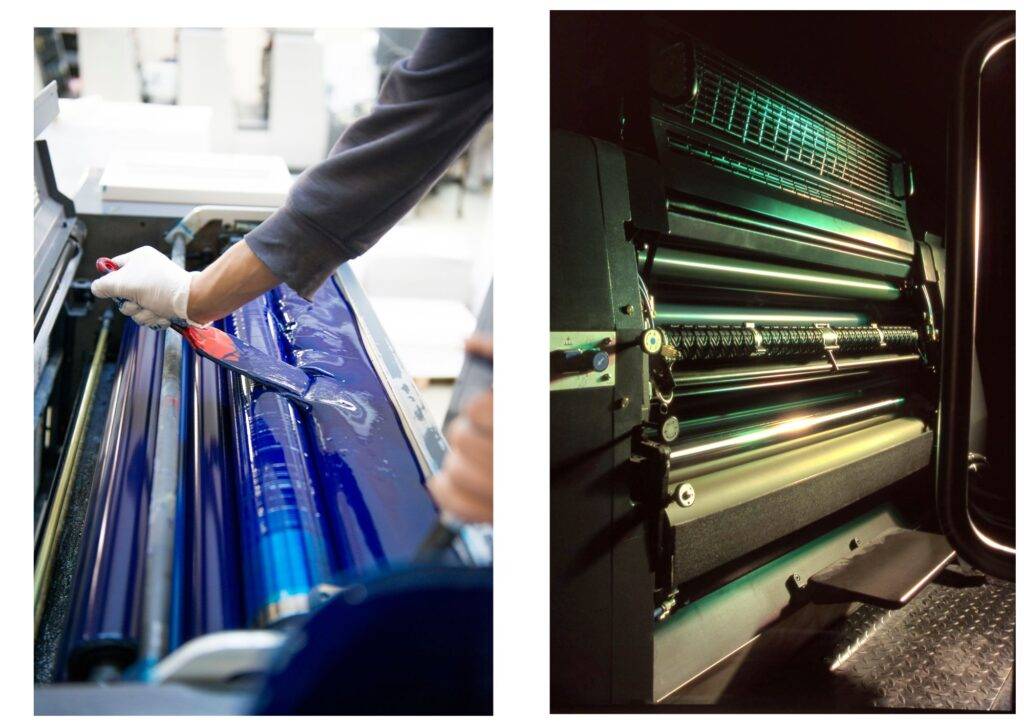

The term offset means to counteract, balance, or to place over against something (Merriam-Webster, 2024). In the context of package printing, offset printing implies that the ink is not directly transferred to the substrate. This technique, also technically referred to as lithography, transfers the ink from an etched sheet plate to a rubber sheet or blanket. The rubber blanket with ink then stamps the design onto the printing surface.

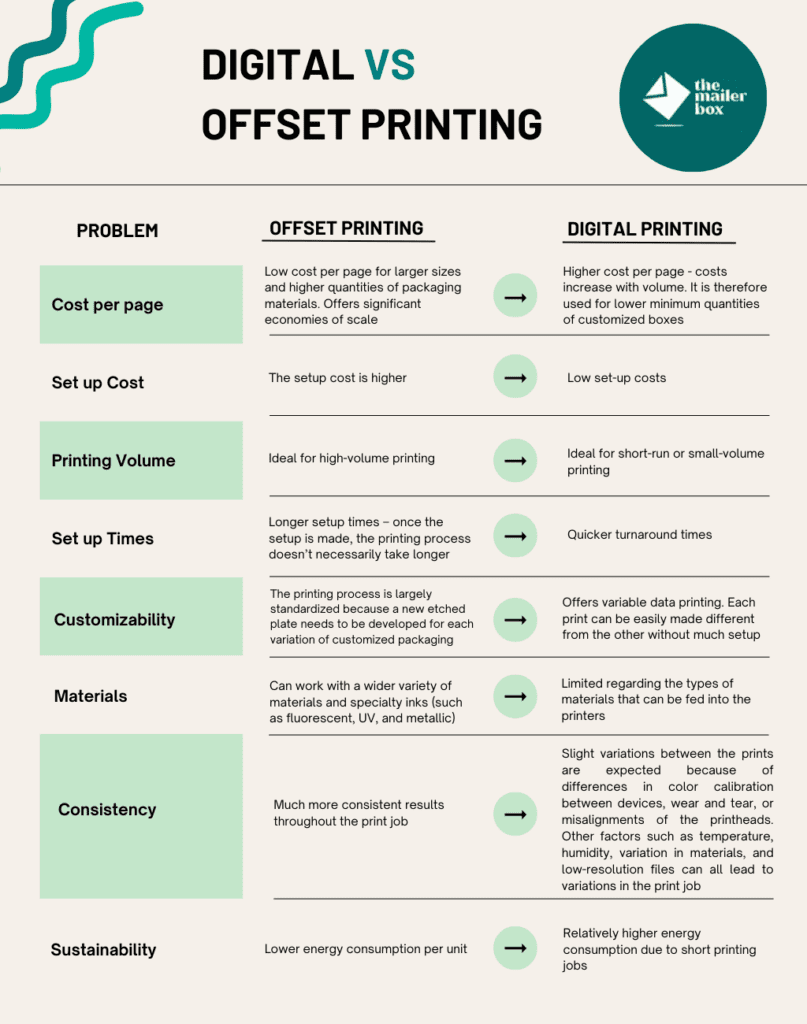

For customized packaging, offset printing is popular for two reasons. Firstly, this process allows for high-quality and consistent results and secondly, it prints at a much cheaper cost per page for higher print volumes. Offset printing achieves its high print quality by using both the CMYK and PMS color models, giving it further versatility. Typically, the printer would use CMYK for full-color printing while the PMS is used for printing spot colors.

After finalizing the artwork, the design is transferred to printing plates (separate for each of the CMYK colors). These plates are mounted onto the plate cylinders where ink is applied to them. From the plates, the ink is transferred to the rubber blanket and then onto the printed surface. The printing material is fed into the process through a press and each color is sequentially applied to build the final image. Once printing is finalized, the material is passed through a drying process to cure the ink. Finally, if required, the printed and dried material would undergo a finishing process such as lamination or varnishing.

Offset printing is one of the best print solutions that balances quality with cost quite effectively. It can work well with a variety of materials and finishing add-ons thus allowing you to be quite creative with the look and feel of your customized boxes.

On the downside, however, the setup time for offset printing is higher and the printing process itself is standardized. These reasons make offset printing much more suitable for jobs with higher volumes requiring standard printing.

DIGITAL PRINTING

To achieve a digital print, all you need to do is to set up the design file and then share it with the printer. At this stage, the designer needs to ensure that the colors, alignment, and other print requirements are double-checked. The digital printing method uses inkjet or electrophotographic printing methods and transfers the ink directly onto the printing surface. This process is similar to the printers connected to personal computers but on a larger scale.

Inkjet printing is known for its vibrant results and customizability. Inkjet is a type of printer that selectively deposits ink onto the printing surface. The ink is then dried using UV light to ensure that it adheres to the surface properly and is not smudged.

On the other hand, electrophotographic printing, more commonly known as laser printing uses toner particles to transfer the image onto the printing surface. The process of sending a print command to the laser printer is the same as that for an inkjet printer. The difference is in the mechanism with which the two printers work.

In electrophotographic printing, an electrostatic image is created by the laser beam selectively charging the photoconductive drum that attracts the toner particles. Then toner particles are transferred onto the packaging material to create the desired image. As the final step, the toner is fused using heat or pressure. The results of laser printing are not as vibrant as those of inkjet printing, but it is more economical, and the actual printing process is much shorter.

KEY DIFFERENCES BETWEEN OFFSET AND DIGITAL PRINTING

FLEXOGRAPHIC PRINTING

Flexographic printing as the name implies typically works with flexible substrates and is therefore commonly used for label printing. It is a type of relief printing that works best with higher volumes.

To set up flexographic printing, rubber or photopolymer printing plates are mounted onto a printing cylinder. These plates have raised images of the print design that transfer the design to the printing material as the plate rotates against it.

Once the print is complete, the substrate goes through a UV drying process followed by additional finishing processes if and as required.

Flexographic printing requires a pre-planned setup, but once that’s complete, it can print large volumes of packaging material at a high speed. While this printing method is most popular for printing labels and bags, it can also be used for printing on corrugated boxes.

GRAVURE PRINTING

Gravure printing or rotogravure printing is known for its high-quality print results with rich colors and consistent results, making it one of the more expensive printing methods.

Gravure printing is typically the choice when the print quality is of the utmost importance such as for printing catalogues, financial or company reports, certificates, high-end magazines, and similar other items.

For this technique, the design is etched directly on steel or copper cylinders. These cylinders are submerged in ink and after wiping off the excess ink, are rolled over the printing surface thereby transferring the design onto the substrate.

The etching is done either by chemical or laser depending on customer and design requirements. This choice would then have an impact on the cost of an already expensive printing process.

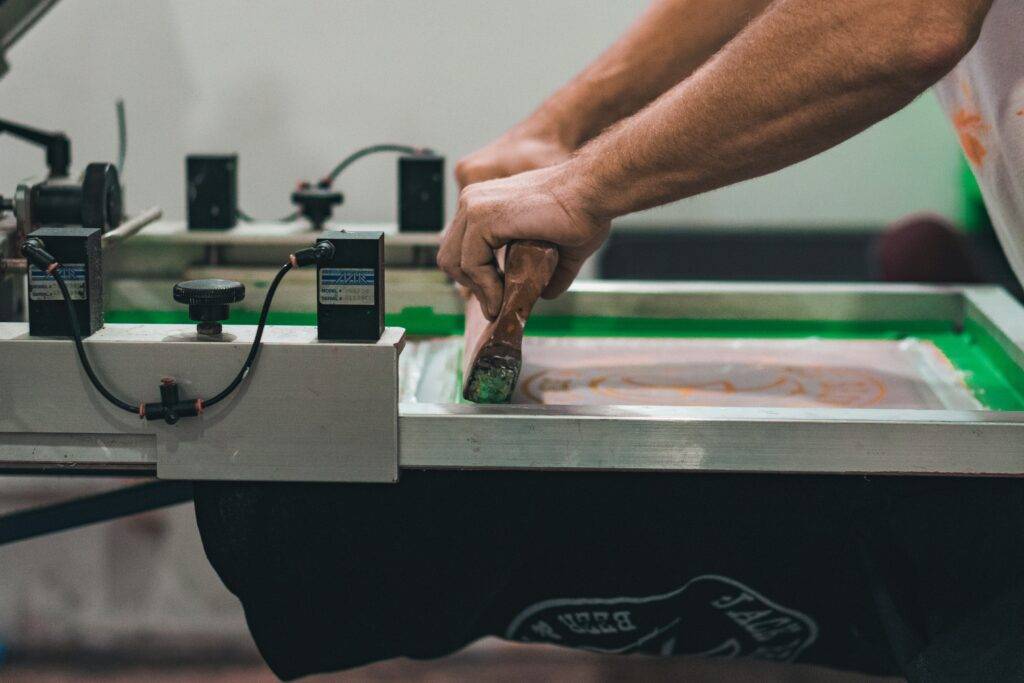

SCREEN PRINTING

Screen printing is typically used to print on fabrics, but it can still be used for package printing to create special effects thus making its way to the article!

A screen print is achieved by developing a stencil of the desired image on a transparent film. This film is placed on top of a mesh screen (made of fabrics such as nylon silk or polyester) that has been stretched over a frame. Once the stencil film is positioned, ink is spread evenly all over the stencil using a squeegee. This ink passes through the open areas of the stencil, through the screen, and onto the substrate below thereby creating the desired image.

Screen printing in packaging is used for creating special effects and for printing on irregular or non-flat surfaces. While screen printing can add fun and creative elements to the packaging, it is quite labor-intensive and unsuitable for printing on larger volumes.

PRINTING METHOD AND TYPES OF PACKAGING

But which printing method is the right one for your brand?

This decision depends on several factors such as time constraints, required print quality, printing and packaging budgets, and the facilities your custom box manufacturer offers.

While your custom box manufacturer will be able to guide you about the best printing technique for your requirements, the following are some key points that you should consider:

– If you are looking for customized luxury boxes such as high-end product boxes or holiday gift boxes, offset printing would deliver the best results! The print would be sharp, high-def, and consistent. The print method would also provide better control of cost per print. This makes offset printing a typical choice for printing on customized rigid boxes.

– For orders requiring smaller volumes, especially where a high-quality print is not the primary concern, digital printing can allow you to have your packaging delivered to you much more quickly. You can opt for digital printing when developing prototypes or for print jobs requiring variable data printing.

– For orders where print quality is not a concern, but the volume is still sufficiently large, you would benefit significantly from offset printing in terms of cost per print. At The Mailer Box, we frequently choose offset printing for medium to high-volume packaging orders to transfer the cost benefit to our customers.

You can further discuss the various printing methods with one of our friendly experts at +18017834566 or at [email protected]. The Mailer Box excels in every type of printing technique and provides its customers with all possible printing options. Our Mailer Box team will be able to guide you toward a high-quality and budget-friendly printing method according to your requirements.

Hope you understand the different printing methods in packaging a little better than before. If so, do give the article a thumbs up!

Screen printing is typically used to print on fabrics, but it can still be used for package printing to create special effects thus making its way to the article!

A screen print is achieved by developing a stencil of the desired image on a transparent film. This film is placed on top of a mesh screen (made of fabrics such as nylon silk or polyester) that has been stretched over a frame. Once the stencil film is positioned, ink is spread evenly all over the stencil using a squeegee. This ink passes through the open areas of the stencil, through the screen, and onto the substrate below thereby creating the desired image.

Screen printing in packaging is used for creating special effects and for printing on irregular or non-flat surfaces. While screen printing can add fun and creative elements to the packaging, it is quite labor-intensive and unsuitable for printing on larger volumes.

PRINTING METHOD AND TYPES OF PACKAGING

But which printing method is the right one for your brand?

This decision depends on several factors such as time constraints, required print quality, printing and packaging budgets, and the facilities your custom box manufacturer offers.

While your custom box manufacturer will be able to guide you about the best printing technique for your requirements, the following are some key points that you should consider:

– If you are looking for customized luxury boxes such as high-end product boxes or holiday gift boxes, offset printing would deliver the best results! The print would be sharp, high-def, and consistent. The print method would also provide better control of cost per print. This makes offset printing a typical choice for printing on customized rigid boxes.

– For orders requiring smaller volumes, especially where a high-quality print is not the primary concern, digital printing can allow you to have your packaging delivered to you much more quickly. You can opt for digital printing when developing prototypes or for print jobs requiring variable data printing.

– For orders where print quality is not a concern, but the volume is still sufficiently large, you would benefit significantly from offset printing in terms of cost per print. At The Mailer Box, we frequently choose offset printing for medium to high-volume packaging orders to transfer the cost benefit to our customers.

You can further discuss the various printing methods with one of our friendly experts at +18017834566 or at [email protected]. The Mailer Box excels in every type of printing technique and provides its customers with all possible printing options. Our Mailer Box team will be able to guide you toward a high-quality and budget-friendly printing method according to your requirements.

Hope you understand the different printing methods in packaging a little better than before. If so, do give the article a thumbs up!

Ayesha Khubaib

Ayesha has a diverse experience in areas of marketing and management. Over the years, Ayesha has been involved in the packaging sector in various capacities and now aims to share packaging market insights with her readers

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.